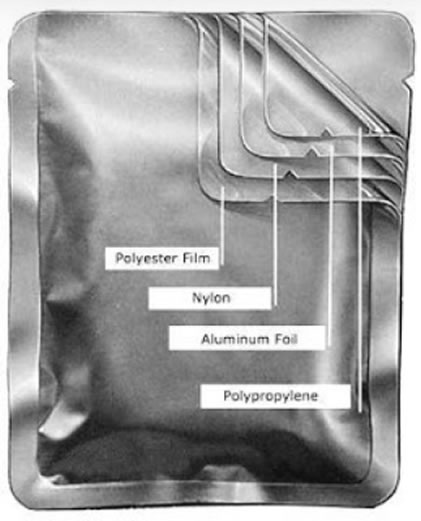

The Big Breakthrough Was the Pouch!

Here is the construction of the breakthrough pouch:

Outer Layer: A tough polyester film which provides protection for the middle layers.

Outer Middle Layer: The newer Nylon layer makes the pouch more durable, adding strength.

Inner Middle Layer: The key to the pouch’s shelf stability … aluminum foil, the most effective and economical barrier to moisture, light and oxygen. The result is no refrigeration or freezing will ever be required.

Inner Layer: Next is a very special polypropylene film. It is compatible with the widest variety of foods so that no “canned” or other unwanted taste is added to the food. It also ensures an exceptionally strong heat seal.

MRE Shelf Life

A main concern in the development and testing of rations for our armed forces has always been shelf life. An amazing amount of research has been done in the development of the retort pouch and the MRE to determine the exact length of time and the exact conditions under which it is safe to store the entrees and the side dishes.

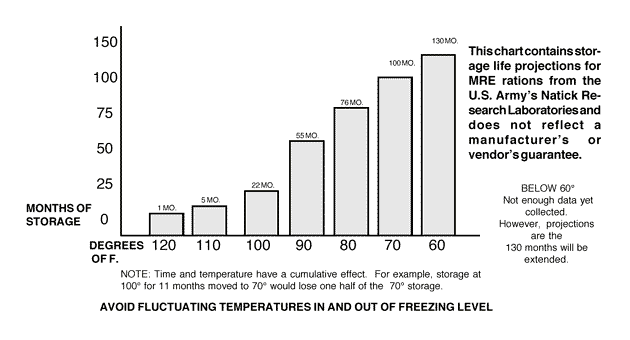

The main thing we have to work with is this shelf life chart compiled by the Army’s Natick Research labs. This gives a very good overview and summary of all the findings gathered from all the testing of MRE products. However, it leaves many questions unanswered. Here are additional facts and observations we have gathered about MRE shelf life:

The main thing we have to work with is this shelf life chart compiled by the Army’s Natick Research labs. This gives a very good overview and summary of all the findings gathered from all the testing of MRE products. However, it leaves many questions unanswered. Here are additional facts and observations we have gathered about MRE shelf life:

- The shelf life ratings shown in the chart were determined by taste panels, panels of “average” people, mostly office personnel at the Natick labs. Their opinions were combined to determine when a particular component or, in this case, the entire MRE ration, was no longer acceptable.

- The shelf life determinations were made solely on the basis of taste, as it was discovered that acceptable nutritional content and basic product safety would extend way beyond the point where taste degradation would occur. This means that MREs would be safe and give a high degree of food value long after the official expiration of the products as determined by taste.

- MRE pouches have been tested and redesigned where necessary according to standards much more strict than for commercial food. They must be able to stand up to abuse tests such as obstacle course traversals in field clothing pockets, storage outdoors anywhere in the world, shipping under extremely rough circumstances, 100% survival of parachute drops, 75% survival of free-fall air drops, severe repetitive vibration (1-hour at 1G vibration), 7,920 individual pouch drops from 20 inches, and individual pouches being subjected to a static load of 200 lbs. for 3 minutes.

- Freezing an MRE retort pouch does not destroy the food inside, but repeated freezing increases the chances that the stretching and stressing of the pouch will cause a break in a layer of the laminated pouch. These pouches are made to withstand 1,000 flexes, but repetitive freezing does increase the failure rate by a small fraction of a percent.

Ready to Eat individual serving pouches are the correct mealtime solution for emergency preparedness, camping, hunting and all outdoor activities!

In 1980, the U.S. Military followed the lead of the U.S. Space program in recognizing the workability of a brand new technology. They used it to overhaul their food rations, resulting in delicious, long-lasting meat & non-meat dinners complete with moisture, gravy and sauce. The big breakthrough was the pouch. Its four special layers allow the food to be sealed and then cooked inside and never exposed to the air again until opened. The resulting taste and texture beats the heck out of the LPR’s (Long Range Patrol Rations – dehydrated and freeze dried rations used during the Vietnam era) and the C-rations (the famous canned rations from WW II). The big difference is the taste. But look at what else the MRE pouches give:

- Shelf life of 3-10 years!

- Not freeze dried! Moisture, gravy and sauce are retained in natural form.

- Ready to eat. Hot in 5 minutes with boiling water. (contaminated and/or dirty water has worked because it never touched the food).

- The food can be eaten cold in an emergency (contents were fully cooked in the sealed pouch).

- Specially developed for maximum nutrition

The production date is visible on all our entrees and on most side dishes, desserts, and other components. The production date is a four digit number (date code) printed on each item. The first digit of the 4 digits represents the year, the last 3 digits represent the day of the year.

Example 1: “2156.” In this example, the “2” represents the year 2012 (a “3” would represent 2013, etc.), the “156” represents the 156th day of the year (about June 4). See the top of the individual box or look on pouch for the date code.

Example 2: “1221.” In this example, the “1” represents the year 2011, the 221 represents the 221st day of the year (about August 8).

First digit definitions:

0 = 2010

1 = 2011

2 = 2012

3 = 2013

4 = 2014

5 = 2015

6 = 2016